Beerta ugu weyn ee codsashada kookaha calcined ee Shiinaha waa warshadaha aluminiumka elektiroonigga ah, oo xisaabiya in ka badan 65% wadarta guud ee kookaha calcined, oo ay ku xigto kaarboon, silikoon warshadeed iyo warshado kale oo dhalaalinaya. Isticmaalka kookaha calcined sida shidaalka ayaa inta badan laga helaa sibidhka, korontadda, dhalooyinka iyo warshadaha kale, iyada oo lagu xisaabtamayo qayb yar.

Waqtigan xaadirka ah, saadka gudaha iyo baahida kookaha calcined asal ahaan waa isku mid. Si kastaba ha ahaatee, sababtoo ah dhoofinta xaddi badan oo baaruud hoose-hooseeya kookaha batroolka sare, wadarta guud ee sahayda gudaha ee kookaha calcined kuma filna, wali waxay u baahan tahay in la keeno dhexdhexaad iyo sare kookaha calcined sulfur si loogu kabo.

Iyadoo la dhisayo tiro badan oo unugyo coking ah sannadihii la soo dhaafay, wax soo saarka kookaha calcined ee Shiinaha ayaa la ballaarin doonaa.

Iyada oo ku xidhan nuxurka baaruudda, waxa loo qaybin karaa kookaha baaruudda sare (kooxaha baaruudda ee ka sarreeya 3%) iyo kookaha baaruudda hoose (kooxda baaruudda ka hooseeya 3%).

Coke sulfur Low waxaa loo isticmaali karaa sidii koollada anodic iyo anode horay loo dubay ee warshadda aluminium iyo graphite electrode ee warshad birta ah.

Kookaha baaruudda ah ee tayadiisu hooseyso (wax ka yar 0.5%) ayaa loo isticmaali karaa in lagu soo saaro graphite electrode iyo wakiilka carbonizing.

Kooke sulfur hooseeya ee tayada guud (ka kooban baaruud wax ka yar 1.5%) ayaa caadi ahaan loo isticmaalaa soo saarista anodes hore loo dubay.

Coke batroolka tayadiisu liidato waxaa inta badan loo isticmaalaa dhalaalinta silikoonka warshadaha iyo soosaarka koollada anodic ah.

Coke-sulfur-sare ayaa caadi ahaan loo isticmaalaa shidaal ahaan dhirta sibidhka iyo dhirta tamarta.

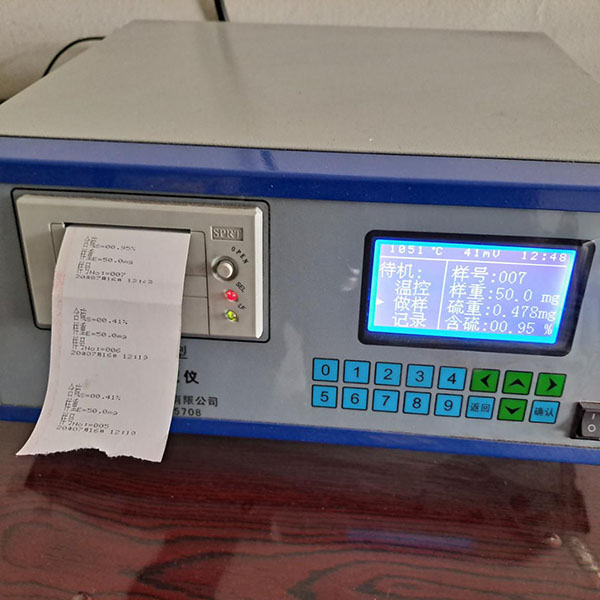

Muunad joogto ah oo sax ah iyo tijaabintu waa qayb ka mid ah habka wax soo saarkayaga.

Kookaha baaruudda sare wuxuu keeni karaa gaas barar inta lagu jiro garaafka, taasoo keentay dildilaaca alaabta kaarboonka.

Maaddooyinka dambaska sarreeya waxay hor istaagi doonaan crystallization ee qaab-dhismeedka oo saameeya waxqabadka alaabta kaarboon

Tallaabo kasta si taxadar leh ayaa loo tijaabin doonaa, waxaan rabnaa inaan sameyno dhab ahaan xogta ogaanshaha.

Sida qayb ka mid ah nidaamka tayadayada xirmo kasta waxaa la miisaami doonaa ugu yaraan 3 jeer, si looga fogaado wax khilaaf ah.

Iyada oo aan cagaarka calcined coke resistivity waa mid aad u sarreeya, u dhow insulator ah, ka dib markii calcining, iska caabin ah ayaa si xoog leh u dhacay, waa u dhiganta iska caabin ah ee kookaha batroolka iyo heerkulka calcined, ka dib 1300 ℃ of caabbinta batroolka kookaha calcined 500 μm Ω m. ama sidaas.

Waqtiga boostada: Dec-20-2024