Coke Calcined waa nooc ka mid ah karburizer iyo kookaha batroolka ee tilmaamo kala duwan.

Tilmaamaha ugu muhiimsan ee alaabta graphite waa ¢150-¢1578 iyo noocyo kale.Waa lagama maarmaanka u ah shirkadaha birta iyo birta, shirkadaha polysilicon silicon warshadaha, shirkadaha emery, warshadaha qalabka hawada iyo alaabada kale.

1: kookaha batroolka

Coke batroolku waa badeecad madow ama cawl madow oo adag oo batrool adag leh oo leh dhalaal macdan ah waana dalool.Waa granular, columnar, ama irbad u eg walxo karbonaceous ah oo ka kooban crystals graphite microscopic.

Coke batroolku wuxuu ka kooban yahay hydrocarbons, 90-97% carbon, 1.5-8% hydrogen, nitrogen, koloriin, baaruud, iyo iskudhisyo bir culus ah.

Coke-ka batroolka waa wax-soo-saarka pyrolysis ee saliidda ceeriin ee qaybta kookeynta ee daahday si loo soo saaro saliid khafiif ah heerkul sare.

Wax soo saarka kookaha batroolka ayaa qiyaastii 25-30% ka ah saliidda ceyriinka ah.

Qiimaha kalooriyada hoose waa qiyaastii 1.5-2 jeer dhuxusha, nuxurka dambaska ka kooban yahay kama badna 0.5%, waxa ku jira isbeddelku waa 11%, tayadiisuna waxay ku dhowdahay anthracite.

2: Halbeegga tayada kookaha batroolka ee kookaha batroolka dib loo dhigay waxa loola jeedaa kookaha ay soo saartay qaybta kookaha oo daahday, sidoo kalena loo yaqaanno kookaha caadiga ah, ma jiro heer u dhigma ##.

Waqtigan xaadirka ah, shirkadaha wax soo saarka gudaha inta badan waxay soo saaraan iyadoo loo eegayo heerka warshadaha SH0527-92 oo ay diyaarisay shirkaddii hore ee Shiinaha Petrochemical.

Heerarka inta badan waxaa loo kala saaraa iyadoo loo eegayo maadada baaruudka ee kookaha batroolka.

No. 1 Coke waxay ku habboon tahay samaynta korantada graphite ee caadiga ah ee warshadaha samaynta birta, iyo sidoo kale loo isticmaalo kaarboon sifeynta aluminium

No. 2 kookaha waxa loo isticmaalaa koollada electrode iyo graphite electrode wax soo saarka ee unug elektrolytic ah (foorna) ee warshadaha dhalaalidda aluminium.

No. 3 kookaha waxaa loo isticmaalaa in wax soo saarka ee silikon carbide (wax shiidi) iyo calcium carbide (calcium carbide), iyo sidoo kale alaabta kale ee carbon, iyo sidoo kale in wax soo saarka ee blocks anode ee smelter aluminium iyo in dhismaha dahaarka carbon. leben ama foornada hoose ee foornada qaraxa.

3: Isticmaalka ugu muhiimsan ee coke batroolka

USES-yada ugu muhiimsan ee kookaha batroolka waa anode horay loo dubay iyo koollada anode ee aluminiumka elektiroonigga ah, soosaarka kaarboon ee wakiilka carbonizing, electrode graphite, dhalada silicon warshadaha iyo shidaalka, iwm.

Marka loo eego qaab dhismeedka iyo muuqaalka kookaha batroolka, badeecada kookaha batroolka waxaa loo qaybin karaa coke-coke irbad, coke isbuunyo, coke projectile iyo coke budo ah:

(1) Coke irbad u qaabaysan, oo leh qaab-dhismeedka irbad-u eg iyo texture fiber, waxaa inta badan loo isticmaalaa sida korantada garaafyada awoodda sare leh iyo ultra-high-power graphite electrode ee birta samaynta.

Sababtoo ah coke cirbaddu waxay leedahay shuruudaha index tayo adag oo ku jira maadada sulfur, content ash, content volatile iyo cufnaanta dhabta ah, waxaa jira shuruudo gaar ah oo ku saabsan tignoolajiyada wax soo saarka iyo alaabta ceeriin ee kookaha irbadda.

(2) Coke isbuunyada, oo leh fal-celin kiimiko oo sarreeya iyo ka kooban wasakh yar, ayaa inta badan loo adeegsadaa warshadaha dhalada aluminium iyo warshadaha kaarboon.

(3) Coke Projectile ama kookaha wareegsan: waa qaab wareegsan iyo dhexroor 0.6-30mm.Guud ahaan waxaa laga soo saaraa baaruud sare iyo hadhaaga asphaltene-sare waxaana loo isticmaali karaa oo kaliya koronto, sibidhka iyo shidaalka kale ee warshadaha.

(4) Coke budada ah: waxaa lagu soo saaraa geeddi-socod dareere ah oo dareere ah oo leh qaybo ganaax ah (dhexroor: 0.1-0.4mm), nuxurka isbeddelka sarreeya iyo fidinta kuleylka sare ee fidinta, sidaas darteed si toos ah looguma isticmaali karo diyaarinta electrode iyo warshadaha kaarboon.

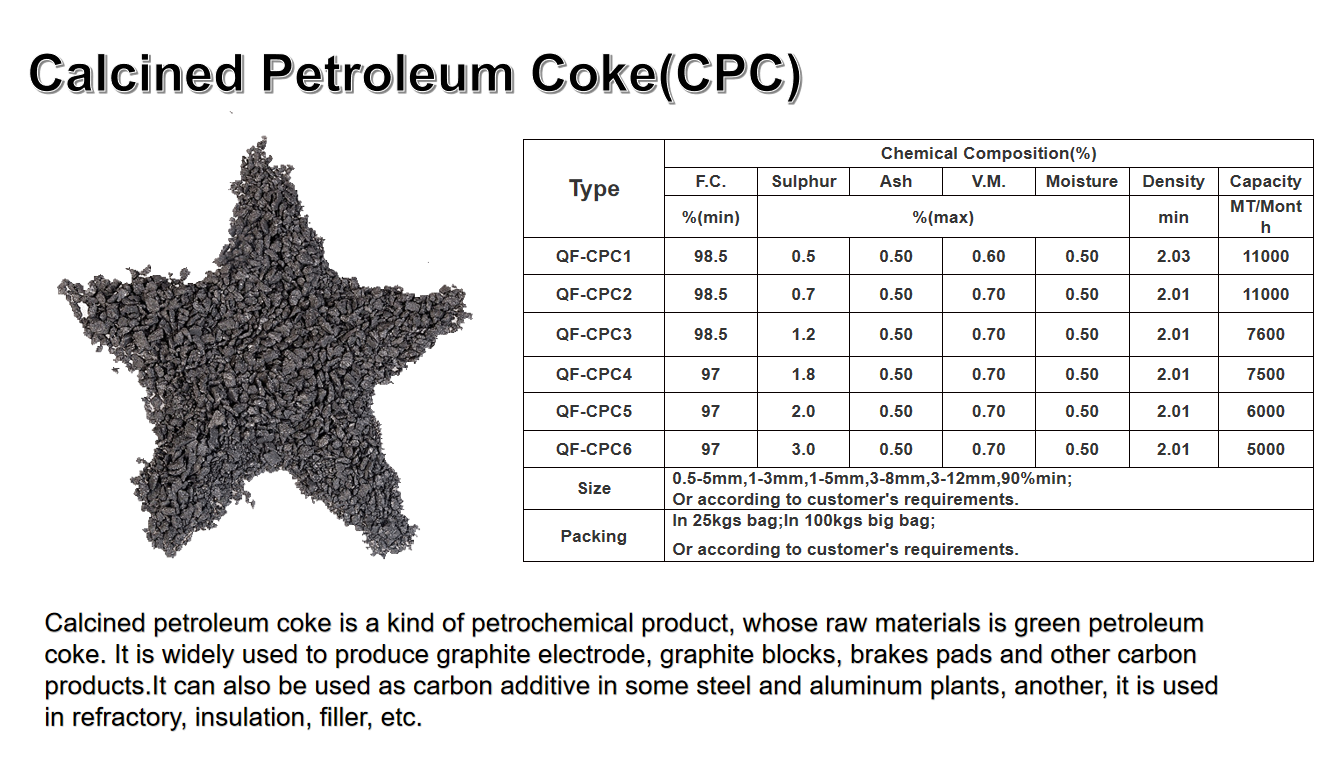

4: Coke batroolka oo la kariyey

Marka graphite electrode ee birta samaynta ama koollada anode (electrode dhalaalaysa) ee aluminium iyo magnesium, si loo sameeyo coke batroolka (coke) buuxiyo shuruudaha, kookaha waa in la calcined.

Heerkulka calcining guud ahaan waa ku dhawaad 1300 ℃, ujeedada taas oo ah in laga takhaluso isbeddelka kookaha naphthol ilaa inta suurtogalka ah.

Sidan oo kale, nuxurka hydrogen ee taranka coke batroolka waa la dhimi karaa, heerka garaafka ee kookaha batroolka waa la hagaajin karaa, xoogga heerkulka sare iyo caabbinta kulaylka ee electrode graphite waa la hagaajin karaa, iyo korantada korantada ee graphite electrode waa la hagaajin karaa .

Calcining waxaa inta badan loo isticmaalaa in lagu soo saaro graphite electrode, alaabta koollada carbon, ciid Diamond, warshadaha fosfooraska heerka-cunto, warshadaha biraha iyo carbide calcium, ka mid ah kuwaas oo electrode graphite si weyn loo isticmaalo.

Coke-ka aan been-abuurka lahayn waxaa si toos ah loogu isticmaali karaa sida kaalshiyam carbide, silicon carbide iyo boron carbide sida walxaha wax lagu shiidi karo.

Waxa kale oo si toos ah loogu isticmaali karaa sida kookaha foornada qarxinta warshadaha biraha ama foornada qarxinta dahaarka leben kaarboon, sidoo kale waxaa loo isticmaali karaa habka shubista kookaha is haysta, iwm.

Waqtiga boostada: Noofambar-20-2020