1.EDM sifooyinka qalabka garaafka.

1.1.Furitaanka xawaaraha mashiinka.

Graphite waa walxo aan bir ahayn oo leh dhibic dhalaalaysa oo aad u sareysa oo ah 3, 650 ° C, halka naxaasta uu leeyahay barta dhalaalka ee 1, 083 ° C, markaa korantada graphite waxay u adkeysan kartaa xaaladaha goobta hadda ka sii weyn.

Marka aagga dheecaanka iyo miisaanka cabbirka korantada ay weyn yihiin, faa'iidooyinka waxtarka sare ee farsamaynta qallafsan ee walxaha garaafka ayaa aad u muuqda.

Heerarka kulaylka ee graphite waa 1/3 kan naxaasta ah, kulaylka ka dhasha habka dheecaanka ayaa loo isticmaali karaa in si wax ku ool ah looga saaro qalabka birta.Sidaa darteed, waxtarka processing ee graphite waa ka sarreeyaa in electrode copper in processing dhexdhexaad ah iyo ganaax.

Sida laga soo xigtay waayo-aragnimada processing, xawaaraha processing dheecaan of graphite electrode waa 1.5 ~ 2 jeer ka dhaqso badan in electrode copper hoos yimaada shuruudaha isticmaalka saxda ah.

1.2. Isticmaalka korantada.

Graphite electrode waxa uu leeyahay dabeecad u adkeysan kara xaaladaha sare ee hadda, marka lagu daro, hoos xaaladda roughing ku habboon, oo ay ku jiraan workpieces steel carbon soo saaray inta lagu guda jiro saarista machining ee content iyo dareeraha shaqada ee kala-goynta heerkulka sare ee qaybaha carbon, saamaynta polarity, hoos. ficilka qayb ka mid ah ka saarista ee content, qayb ka carbon u hoggaansamaan doonaa in ay dusha electrode si ay u sameeyaan lakabka ilaalinta, hubisaa electrode graphite in khasaaraha yar ee machining qallafsan, ama xataa "eber qashinka".

Luminta korantada ugu weyn ee EDM waxay ka timaadaa mashiinada qallafsan.Inkasta oo heerka khasaaruhu uu sarreeyo xaaladaha dejinta ee dhammaystirka, khasaaraha guud sidoo kale waa hooseeyaa sababtoo ah gunnada mashiinka yar ee loo qoondeeyay qaybo.

Guud ahaan, luminta electrode graphite waa ka yar yahay electrode copper in machining qallafsan ee hadda waaweyn iyo in yar ka badan in electrode copper ee dhamaystirka machining.Luminta korantada ee electrode graphite waa la mid.

1.3.Tayada dusha sare.

Dhexroorka walxaha graphite wuxuu si toos ah u saameeyaa qallafsanaanta dusha sare ee EDM.Dhexroorka yari waa, hoos u dhigista dusha sare waa la heli karaa.

Dhawr sano ka hor iyadoo la isticmaalayo qayb phi 5 microns dhexroor walxaha graphite, oogada ugu fiican ayaa lagu gaari karaa oo keliya VDI18 edm (Ra0.8 microns), maalmahan dhexroorka hadhuudh ee alaabta graphite ayaa awooday in ay gaaraan gudahood 3 microns of phi, oogada ugu fiican. wuxuu gaari karaa VDI12 edm deggan (Ra0.4 mu m) ama heer ka sii casrisan, laakiin graphite electrode si uu u milicsado edm.

Maaddada naxaasta ah waxay leedahay iska caabin hoose iyo qaab dhismeed is haysta, waxaana loo habayn karaa si adag iyadoo lagu jiro xaalado adag.Qalafsanaanta dusha sare waxay noqon kartaa wax ka yar Ra0.1 m, waxaana lagu farsamayn karaa muraayad.

Sidaa darteed, haddii mishiinnada dheecaanku ay raacaan dusha sare ee aad u fiican, way ku habboon tahay in loo isticmaalo walxaha naxaasta ah sida electrode, taas oo ah faa'iidada ugu weyn ee korantada naxaasta ee elektiroonigga graphite.

Laakiin electrode copper ka hooseeya xaaladda goob weyn oo hadda, dusha electrode waa u fududahay in ay noqdaan qallafsan, muuqan xitaa dillaac, iyo qalabka graphite ma lahaan lahaa dhibaatadan, shuruudaha qallafsanaan dusha sare ee VDI26 (Ra2.0 microns) oo ku saabsan processing caaryada, isticmaalaya electrode graphite waxaa la samayn karaa laga bilaabo qalafsanaan si ay u baaraandegi fiican, garwaaqsado saamaynta dusha uniform, cilladaha dusha.

Intaa waxaa dheer, iyadoo ay sabab u tahay qaab-dhismeedka kala duwan ee graphite iyo naxaas, barta daxalka dheecaan dusha sare ee electrode graphite waa ka joogto ah ka electrode copper.Sidaa darteed, marka la mid ah dusha sare ee VDI20 ama ka sarreeya la farsameeyo, granularity dusha sare ee workpiece ka baaraandegi by graphite electrode ka badan oo kala duwan, iyo saamaynta dusha hadhuudh this ka fiican yahay saamaynta dusha dheecaan of electrode copper.

1.4. Saxnaanta mashiinka.

Coefficient of balaadhinta kulaylka alaabta graphite waa yar yahay, coefficient of ballaarinta kulaylka ee wax naxaas ah waa 4 jeer in wax graphite, sidaa darteed in processing dheecaanka, graphite electrode waa yar u nugul qallafsanaan ka badan electrode copper, kaas oo heli kara xasilloon iyo in ka badan. saxnaanta processing lagu kalsoonaan karo.

Gaar ahaan marka feeraha qoto dheer iyo cidhiidhiga ah la farsameeyo, heerkulka sare ee maxalliga ah ayaa ka dhigaya korantada naxaasta si fudud u foorarsato, laakiin graphite electrode ma sameeyo.

Electrode copper leh cabirka qoto dheer ee dhexroorka weyn, qiimaha fidinta kulaylka gaar ah waa in la magdhabaa si loo saxo cabbirka inta lagu jiro goobta mashiinka, halka korantada graphite aan loo baahnayn.

1.5.Electrode miisaanka.

Qalabka garaafka waa ka cufan ka yar yahay naxaasta, iyo miisaanka graphite electrode ee mugga la mid ah waa 1/5 oo kaliya oo ka mid ah korantada naxaasta.

Waxaa la arki karaa in isticmaalka graphite uu aad ugu habboon yahay korantada oo leh mug weyn, taas oo si weyn u yaraynaysa culeyska lafdhabarta ee qalabka mashiinka EDM.Electrode-ku ma keeni doono dhib la'aanta isku-xidhka culeyskiisa weyn, wuxuuna soo saari doonaa barokac leexin ah ee farsamaynta, iwm. Waxaa la arki karaa inay muhiimad weyn leedahay in la isticmaalo korantada graphite ee farsamaynta caaryada ballaaran.

1.6.Dhibaatada wax soo saarka Electrode.

Waxqabadka mashiinka qalabka garaafka waa mid wanaagsan.Iska caabbinta goyntu waa 1/4 oo keliya oo naxaas ah.Under xaaladaha processing saxda ah, hufnaanta ee milling graphite electrode waa 2 ~ 3 jeer in electrode copper.

Electrode graphite waa sahlan tahay in la nadiifiyo xagasha, waxaana loo isticmaali karaa in lagu farsameeyo qalabka shaqada kaas oo lagu dhammeeyo electrodes badan oo loo diro hal koronto.

Qaab dhismeedka qaybta gaarka ah ee walxaha graphite ayaa ka hortagaya burrs inay dhacaan ka dib marka la shiilo electrode iyo samaynta, taas oo si toos ah u buuxin karta shuruudaha isticmaalka marka burrs aan si fudud looga saarin qaabaynta adag, sidaas awgeed meesha laga saaro habka loo nadiifiyo gacanta ee electrode iyo ka fogaanshaha qaabka isbeddelka iyo khaladka cabbirka ee ay keento polishing.

Waa in la ogaadaa in, sababtoo ah graphite waa ururin boodh ah, garaafyada wax lagu shido ayaa soo saari doona boodh badan, sidaas darteed mashiinka wax lagu shubo waa inuu leeyahay qalab ururin iyo boodh.

Haddii ay lagama maarmaan tahay in la isticmaalo edM si loo farsameeyo electrode graphite, waxqabadkeedu ma fiicna sida walxaha naxaasta ah, xawaaraha goynta wuxuu ku saabsan yahay 40% ka hooseeya naxaasta.

1.7.Electrode rakibida iyo isticmaalka.

Alaabta graphite waxay leedahay hanti isku xidhid wanaagsan.Waxaa loo isticmaali karaa in lagu xidho garaafyada qalabka lagu rakibo iyada oo la shiiday electrode-ka iyo soo daynta, taas oo badbaadin karta habka mashiinka daloolka mashiinnada qalabka elektaroonigga ah oo badbaadiya wakhtiga shaqada.

Qalabka graphite waa mid jajaban, gaar ahaan electrode yar, cidhiidhi ah iyo dheer, kaas oo si sahlan loo jebiyo marka la isticmaalo xooga dibadda ah inta lagu jiro isticmaalka, laakiin waxay isla markiiba ogaan kartaa in electrode uu dhaawacmay.

Haddii ay tahay electrode copper, kaliya way foorarsan doontaa mana jabin doonto, taas oo ah mid aad khatar u ah oo ay adag tahay in la helo habka isticmaalka, waxayna si fudud u horseedi doontaa qashinka shaqada.

1.8.Qiimaha.

Maaddada Copper waa kheyraad aan dib loo cusboonaysiin karin, isbeddelka qiimaha ayaa noqon doona mid aad u qaali ah, halka qiimaha alaabta garaafyada ay u egtahay in ay dejiso.

Qiimaha alaabta Copper sii kordhaya sannadihii la soo dhaafay, saarayaasha waaweyn ee graphite hagaajinta habka wax soo saarka ee graphite ka dhigi faa'iido tartan, hadda, hoos mugga la mid ah, guud ahaan qiimaha alaabta electrode graphite iyo qiimaha qalabka electrode copper waa arrin, laakiin graphite wuxuu gaari karaa habayn hufan, ka badan isticmaalka electrode copper si loo badbaadiyo tiro badan oo saacadaha shaqada, oo u dhiganta si loo yareeyo kharashka wax soo saarka si toos ah.

Si loo soo koobo, oo ka mid ah sifooyinka 8 edM ee electrode graphite, faa'iidooyinkeedu waa cad yihiin: waxtarka milling electrode iyo dheecaanka dareeraha ayaa si weyn uga fiican kan electrode copper;Electrode weyn ayaa leh miisaan yar, xasilloonida cabbirka wanaagsan, korantada khafiifka ah ma fududa in la qaabeeyo, iyo texture dusha ayaa ka fiican electrode copper.

Khasaaraha alaabta graphite waa in aysan ku habooneyn ka shaqeynta dheecaanka dusha sare ee VDI12 (Ra0.4 m), iyo waxtarka isticmaalka edM si loo sameeyo electrode waa mid hooseeya.

Si kastaba ha ahaatee, marka laga eego dhinaca wax ku ool ah ee view, mid ka mid ah sababaha muhiimka ah ee saameeya kor u qaadida wax ku ool ah qalabka graphite ee Shiinaha waa in mishiinka processing graphite gaar ah loo baahan yahay si ay u milling electrodes, taas oo soo bandhigaysa shuruudaha cusub ee qalabka processing ee shirkadaha caaryada, qaar ka mid ah shirkadaha yaryar. waxaa laga yaabaa in aan xaaladdan qabin.

Guud ahaan, faa'iidooyinka korantada garaafyada ayaa daboolaya inta badan munaasabadaha farsamaynta edM, waxayna u qalmaan faafinta iyo adeegsiga, oo leh faa'iidooyin waqti dheer ah oo la taaban karo.La'aanta farsamaynta dusha sare ee wanaagsan waxaa lagu samayn karaa isticmaalka korantada naxaasta.

2.Xulashada qalabka graphite electrode ee EDM

Qalabka garaafyada, inta badan waxaa jira afar tilmaame oo si toos ah u go'aamiya waxqabadka alaabta:

1) Celceliska dhexroorka walxaha walxaha

Celceliska dhexroorka walxaha walxuhu wuxuu si toos ah u saameeyaa xaaladda dheecaanka walxaha.

Celcelis ahaan qayb ka mid ah walxaha garaafka waa, inta lebbiska ah ee dheecaanku waa, aad u xasilloon xaaladda dheecaanku waa, tayada korka ayaa ka sii fiican, iyo yaraanta khasaaraha.

Celcelis ahaan cabbirka qayb ka weyn yahay, heerka saarista ka wanaagsan waxaa lagu heli karaa machining qallafsan, laakiin saamaynta dusha sare ee dhamaystirka waa liidata iyo khasaaraha electrode waa weyn.

2) Xoog foorarsiga walxaha

Awoodda dabacsanaanta maaddadu waxay si toos ah u muujinaysaa xooggeeda, taas oo muujinaysa cidhiidhiga qaab dhismeedka gudaha.

Maaddada xoogga sare leh waxay leedahay wax-qabad iska caabin ah oo dareere ah.Qalabka elektiroonigga ah ee saxda ah, walxaha xoogga leh waa in la doortaa inta suurtogalka ah.

3) Engegnaanta xeebta ee alaabta

Graphite way ka adag tahay qalabka birta, luminta qalabka wax lagu gooyo ayaa ka weyn kan birta goynta.

Isla mar ahaantaana, adkaanta sare ee walxaha garaafka ee xakamaynta luminta dareeraha ayaa ka fiican.

4) caabbinta dabiiciga ah ee walxaha

Heerka dheecaanka walxaha graphite ee leh iska caabin sare oo dabiici ah ayaa ka gaabis ahaan doona kuwa iska caabbinta hooseeya.

Markasta oo ay sare u kacdo iska caabbinta dabiiciga ah, waa yaraanta luminta electrode-ka, laakiin marka ay sii badato iska caabbinta dabiiciga ah, xasiloonida dheecaanka ayaa saameyn doonta.

Waqtigan xaadirka ah, waxaa jira darajooyin badan oo kala duwan oo garaafyada ah oo laga heli karo alaab-qeybiyeyaasha garaafyada hormuudka ka ah adduunka.

Guud ahaan marka loo eego celceliska dhexroorka walxaha garaafka ee agabyada garaafka in la kala saaro, dhexroorka qayb ≤ 4 m waxaa lagu qeexaa sida garaafyada ganaaxa, Qaybaha 5 ~ 10 m waxaa lagu qeexaa garaaf dhexdhexaad ah, qaybaha 10 m ee kor ku xusan waxaa lagu qeexaa garaafyo qalafsan.

Inta yar ee dhexroorka qaybtu waa, qaaliga alaabtu waa qaali, qalabka garaafka ku habboon ayaa lagu dooran karaa iyadoo loo eegayo shuruudaha iyo kharashka EDM.

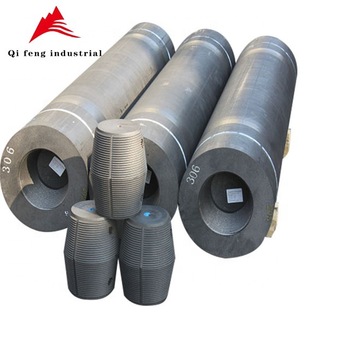

3.Fabrication of graphite electrode

Elektroodhka graphite waxa inta badan lagu sameeyaa wax-shiidid.

Marka laga eego dhinaca tignoolajiyada farsamaynta, graphite iyo copper waa laba walxood oo kala duwan, iyo sifooyinkooda goynta ee kala duwan waa in la maareeyaa.

Haddii korantada graphite lagu farsameeyo habka korantada naxaasta, dhibaatooyinka ayaa si lama filaan ah u dhici doona, sida jajabka soo noqnoqda ee xaashida, taas oo u baahan isticmaalka qalabka goynta habboon iyo goynta goynta.

Machining graphite electrode ka badan naxaas qalab electrode xirtaan, on tixgelin dhaqaale, doorashada qalab carbide waa tan ugu dhaqaalaha badan, dooro qalab daahan diamond (loo yaqaan mindida graphite) qiimaha waa ka qaalisan, laakiin daahan diamond qalab nolosha adeeg dheer, saxan processing sare. guud ahaan faa'iidada dhaqaale waa wanaagsan tahay.

Baaxadda xagasha hore ee qalabka ayaa sidoo kale saameynaysa nolosha adeegga, 0 ° xagasha hore ee qalabku wuxuu noqon doonaa ilaa 50% ka sarreeya 15 ° xagasha hore ee nolosha adeegga qalabka, goynta xasilloonida ayaa sidoo kale ka fiican, laakiin Xagasha weyn, oo ka sii fiican mashiinka mashiinka, isticmaalka xagasha 15 ° ee qalabku wuxuu gaari karaa mashiinka mashiinka ugu fiican.

Xawaaraha goynta ee mashiinada waxaa lagu hagaajin karaa iyadoo loo eegayo qaabka electrode, sida caadiga ah 10m / min, oo la mid ah machining ee aluminium ama caag ah, qalab goynta si toos ah iyo off workpiece in machining qallafsan kartaa, iyo ifafaale of xagal burburka iyo kala qaybsanaantu way fududahay in lagu sameeyo dhamaystirka mishiinka, iyo habka mindida fudud ee socodka degdega ah ayaa badanaa la qaataa.

Electrode graphite ee habka goynta ayaa soo saari doona boodh badan, si looga fogaado walxaha graphite ee lagu neefsado dunta mishiinka iyo furka, waxaa jira laba xal oo waaweyn oo hadda ah, mid waa in la isticmaalo mashiinka wax lagu sameeyo ee garaafka, kan kalena waa xarunta caadiga ah ee wax lagu sameeyo. dib-u-habayn, oo lagu rakibay qalab gaar ah oo lagu ururiyo boodhka.

Garaafyada khaaska ah ee mashiinka wax lagu shubo xawaaraha sare ee suuqa ayaa leh waxtarka wax-shiidka oo sarreeya wuxuuna si fudud u dhamaystiri karaa wax-soo-saarka korantada adag ee saxda ah iyo tayada sare ee wanaagsan.

Haddii EDM loo baahan yahay si loo sameeyo graphite electrode, waxaa lagu talinayaa in la isticmaalo qalabka garaafyada ganaaxa leh dhexroor qayb yar.

Waxqabadka mashiinka garaafka waa mid liita, dhexroorka qaybtu waa yar yahay, way sii badan tahay waxtarka goynta ayaa la heli karaa, dhibaatooyinka aan caadiga ahayn sida jebinta siliga soo noqnoqda iyo dusha sare waa laga fogaan karaa.

4.EDM ee korantada graphite

Xulashada xuduudaha EDM ee graphite iyo naxaasta ayaa aad uga duwan.

Halbeegyada EDM inta badan waxaa ka mid ah hadda, ballaca garaaca wadnaha, farqiga garaaca wadnaha iyo polarity.

Kuwan soo socdaa waxay qeexayaan aasaaska isticmaalka macquulka ah ee cabbirradan waaweyn.

Cufnaanta hadda ee graphite electrode guud ahaan waa 10 ~ 12 A/cm2, aad uga weyn kan korantada naxaasta ah.Sidaa darteed, inta u dhaxaysa xadka hadda la oggol yahay ee aagga u dhigma, weynaanta hadda ayaa la doortaa, sida ugu dhaqsaha badan ee xawaaraha wax-qabadka graphite ayaa noqon doona, yaraanta khasaaraha korantada ayaa noqon doonta, laakiin qallafsanaanta dusha ayaa noqon doonta dhumuc weyn.

Baaxadda ballaca garaaca garaaca wadnaha waa, hoos u dhaca khasaaraha korantada ayaa noqon doona.

Si kastaba ha ahaatee, ballaca garaaca wadnaha oo weyn ayaa ka dhigi doona xasiloonida habaynta, iyo xawaaraha farsamaynta oo gaabis ah oo dusha sare leh.

Si loo xaqiijiyo luminta korantada yar inta lagu jiro mashiinada qallafsan, balac garaaca garaaca garaaca ayaa inta badan la isticmaalaa, kaas oo si wax ku ool ah u ogaan kara mashiinada luminta hooseeya ee electrode garaafyada marka qiimuhu u dhexeeyo 100 iyo 300 US.

Si loo helo dusha sare iyo saamaynta dheecaanka deggan, waa in la doortaa ballac yar oo garaaca wadnaha ah.

Guud ahaan, ballaca garaaca wadnaha ee electrode graphite wuxuu ku saabsan yahay 40% ka yar kan korantada naxaasta

Farqiga garaaca garaaca wadnaha ayaa inta badan saameeya xawaaraha mashiinka dheecaanka iyo xasiloonida mishiinka.Qiimaha weyn, ayaa si ka sii wanaagsan u noqon doona xasilloonida makiinadu, taas oo waxtar u leh helitaanka lebbiska dusha sare, laakiin xawaaraha mashiinka waa la dhimi doonaa.

Marka la eego xaaladda hubinta xasilloonida processing, waxtarka sare ee waxtarka ayaa lagu heli karaa iyadoo la dooranayo faraqa garaaca wadnaha oo yar, laakiin marka gobolka dheecaanku uu yahay mid aan xasilloonayn, waxtarka sare ee waxqabadka ayaa la heli karaa iyadoo la dooranayo faraqa garaaca wadnaha oo weyn.

Mashiinka dareeraha elektiroonigga ah ee graphite, farqiga garaaca garaaca iyo ballaca garaaca garaaca waxaa badanaa lagu dhejiyaa 1: 1, halka mashiinka korantada naxaasta, farqiga garaaca garaaca iyo ballaca garaaca garaaca inta badan lagu dhejiyaa 1: 3.

Marka la eego habaynta garaafyada xasilan, saamiga u dhigma ee u dhexeeya farqiga garaaca garaaca iyo ballaca garaaca garaaca waxaa lagu hagaajin karaa 2:3.

Marka laga hadlayo nadiifinta garaaca wadnaha yaryar, waxay faa'iido u leedahay in la sameeyo lakab daboolan oo ku yaal dusha sare ee korantada, taas oo waxtar u leh si loo yareeyo khasaaraha korantada.

Doorashada polarity ee graphite electrode ee EDM asal ahaan waxay la mid tahay kan korantada naxaasta.

Marka loo eego saamaynta polarity ee EDM, mashiinnada polarity togan ayaa inta badan loo isticmaalaa marka mashiinka dhinta birta, taas oo ah, korantadu waxay ku xidhan tahay cirifka togan ee sahayda korantada, iyo workpiece waxay ku xidhan tahay cirifka taban ee korontada.

Isticmaalka ballaca hadda iyo garaaca garaaca wadnaha, doorashada mashiinada polarity togan waxay gaari kartaa khasaare aad u hooseeya.Haddii polarity-ku khaldan yahay, luminta korantadu waxay noqon doontaa mid aad u weyn.

Kaliya marka dusha sare loo baahan yahay in si fiican loo farsameeyo wax ka yar VDI18 (Ra0.8 m) iyo ballaca garaaca garaaca waa mid aad u yar, farsamaynta polarity xun waxaa loo isticmaalaa si loo helo tayada dusha sare, laakiin khasaaraha electrode waa weyn.

Hadda qalabka mashiinka CNC edM waxay ku qalabaysan yihiin cabbirrada mishiinnada dareeraha garaafka.

Isticmaalka xuduudaha korantada waa caqli-gal waxaana si toos ah u dhalin kara nidaamka khabiirka ee qalabka mashiinka.

Guud ahaan, mishiinka u habayn kara xuduudaha processing la hagaajiyey by xulashada labada lamaane wax, nooca codsiga, qiimaha roughness dusha iyo inputting aagga processing, qoto dheer processing, miisaanka electrode, iwm inta lagu guda jiro barnaamijka.

U dejiso graphite electrode of edm mishiinka qalab maktabad qani ah xuduudaha processing, nooca wax dooran kartaa in graphite aan dhab ahayn, graphite, graphite dhigma noocyo kala duwan oo wax workpiece, si ay u qaybiyaan nooca codsiga ee heerka, jeexdin qoto dheer, bar fiiqan, weyn. aagga, dalool weyn, sida ganaax, sidoo kale waxay bixisaa khasaare hoose, heerka, hufnaanta sare iyo wixii la mid ah noocyada badan ee doorashada mudnaanta processing.

5.Gabagabadii

Qalabka cusub ee graphite electrode wuxuu mudan yahay in si xoog leh loo shaaciyo faa'iidooyinkeedana si tartiib tartiib ah ayaa loo aqoonsan doonaa oo ay aqbali doonaan warshadaha wax soo saarka caaryada gudaha.

Xulashada saxda ah ee qalabka elektiroonigga ah ee graphite iyo hagaajinta xidhiidhada farsamada ee la xidhiidha waxay keeni doontaa waxtar sare, tayo sare leh iyo faa'iido qiimo jaban shirkadaha wax soo saarka caaryada.

Waqtiga boostada: Dec-04-2020