UHP Graphite Electrodes Loo Isticmaalay EAF dhalaalid/LF sifaynta inta lagu jiro wax soo saarka birta

Faahfaahin degdeg ah:

Meesha Asal ahaan: Hebei, Shiinaha (Dhul-weynaha)

Magaca SummadaQF

Nooca: Qalabka Electrode

CodsigaBirta Samaynta/Dharka birta

Dhererka: 1600 ~ 2800mm

Darajo: HP

iska caabinμΩ.m): <6.2

Cufnaanta muuqata (g/cm³ ): >1.67

Balaadhinta kulaylka (100-600℃) x 10-6/℃: <2.0

Xoog Jilicsan (Mpa): >10.5

ASH: 0.3% ugu badnaan

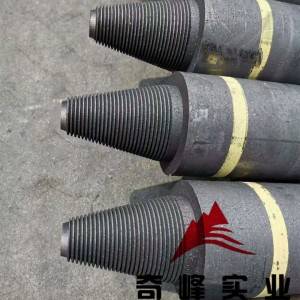

Nooca ibta naaska: 3TPI/4TPI/4TPIL

Walxaha ceeriin: Irbad Petroleum Coke

Sarraynta: Heerka Isticmaalka hooseeya

Midabka: Cawlan madow

Dhexroorka: 300mm, 400mm, 450mm, 500mm, 600mm, 650mm, 700mm

Awood-siinta

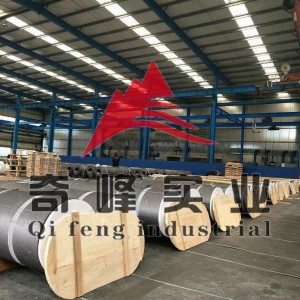

3000 Tan/Tan bishii

Baakadeynta iyo gaarsiinta

Faahfaahinta Baakadaha:

Sariiraha alwaaxda caadiga ah ama sida waafaqsan shuruudaha macmiilka.

DekeddaDekada Tianjin

Faa'iidada

(1) faa'iidooyinka electrode graphite waa hab fudud processing, heerka saarista dheecaan sare machining, khasaaraha graphite waa yar yahay, Sidaa darteed, qaar ka mid ah macaamiisha mashiinka dhimbiil ku salaysan kooxda siiyey ilaa electrode naxaas ah iyo halkii electrode.In dheer, qaar ka mid ah qaabka gaarka ah ee electrode ah ma laga samayn karaa naxaas ah, laakiin graphite waa sahlan tahay in la qaabeeyo, iyo electrode naxaas ah waa culus yahay, ma ku haboon yahay codsiga mashiinada qaar ka mid ah qalabka korontada, kuwaas oo sabab u ah qalabka korontada qaar ka mid ah. electrode.

(2) electrode graphite waa sahlan tahay in la farsameeyo, iyo xawaaraha processing si cad waa ka dhaqso badan electrode. Tusaale ahaan, graphite waxaa baaraandegi by habka milling, taas oo ah 2-3 jeer ka dhaqso badan biraha kale oo aan u baahnayn processing gacanta dheeraad ah, halka electrode copper u baahan yahay Manual shiidi.Similarly, haddii aad isticmaasho xarun processing graphite-xawaaraha sare si ay u sameeyaan electrode ah, wax dhibaato ah oo dheeraad ah ma noqon doonto, iyo kuwan waxaa jiri doona si hufan oo wax ku ool ah. Qalab adag oo ku habboon iyo garaafyada ayaa yarayn kara xirashada qalabka iyo dhaawaca korantada naxaasta. Marka la barbar dhigo wakhtiga wax lagu shiidayo ee u dhexeeya korantada graphite iyo korantada naxaasta, korantada graphite waa 67% ka dhakhso badan electrode naxaasta. Mashiinka dareeraha ee xaaladaha guud, waqtiga processing ee electrode graphite waa 58% ka dhaqso badan in electrode naxaas ah. Natiijo ahaan, waqtiga processing si weyn ayaa hoos u dhacay iyo kharashka wax soo saarka waa la dhimay.

(3) design ee electrode graphite ka duwan yahay in warshadda electrode.Max badan oo naxaas ah dhaqameed sida caadiga ah ee ka baaraandegidda qallafsan ee electrode copper iyo dhinacyada dhamaystirka leeyihiin qadarka kala duwan ee loo qoondeeyey, iyo electrode graphite waxaa loo isticmaalaa ku dhawaad isla qadarka kaydsan, taas oo yaraynaysaa CAD / CAM iyo jeer processing mishiinka, sababtan oo keliya, waa ku filan si aad u hagaajiyo sax ah ee dalool caaryada.